To understand the price of canning equipment, first we need to know what specific canning equipment is required for a complete canning production line. Let us briefly understand the specific equipment.

Three-piece can production line equipment classification: Three-piece can production line manufacturing equipment is divided into cutting equipment, forming welding equipment, drying equipment, rolling equipment, slitting equipment, necking equipment, embossing molding equipment, turning equipment Side equipment, capping equipment, can sealing equipment, leak detection equipment, full internal spray equipment, drying equipment, stacking equipment, packing, etc.

I.Empty can preparation equipment mainly includes: cutting equipment, parting equipment, coating scraping equipment

① Cutting board equipment is used to cut the large sheet of tinplate into pieces of the size required for canning or punching. Its process flow is as follows:

Feeding and cutting → finishing

② Scribing equipment is a device for scoring the uncoiling line or slitting line on the can body blank. Its role is to draw a trace of a certain depth on the cut can body material in order to separate the finished can body from the scribe line.The process is as follows:

Feeder → Single sheet feeding and feeding → marking → selection

Scribing equipment is available in automatic or semi-automatic stand-alone form, as well as in combination with can body welding and forming machines.

③ The coating layer scraping equipment is used to partially scrape the surface coating of the cut can body sheet to facilitate resistance welding (the equipment is not needed to leave the paint plate empty). The process flow is as follows:

Feeder → Single sheet feeding→ Scraping → Stacking

The price of the preparation equipment is about: USD10000-70000

Second, can body forming welding equipment

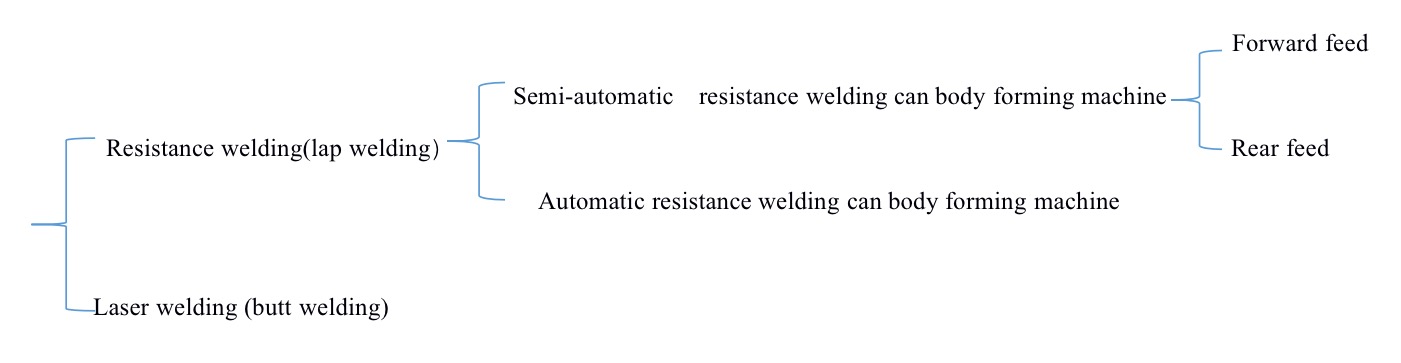

(1)Classification of can body forming and welding equipment

The price of can body forming and welding equipment is about: USD10000-50000

Third, the can body embossing, expanding equipment

(1)Characteristics of embossing and expanding of the can body The embossing or expanding of the can body can be changed into various cross-section (longitudinal or cross-sectional) shapes.

This can is a fancy can. Pattern cans can be divided into two types: one type is round, which is characterized in that the shape of the mouth of the lid keeps the original shape of the round can, and the middle part of the can can be changed in shape according to user requirements, such as barrels Shape, drum shape, vase shape, square, polygon, cone, etc., this type of can is called an embossing can (shapping fancy can); another type of can is shaped, which is characterized by a non-circular lid shape, and The shape of the can body and the lid are basically the same. Common types of cans are: square, rectangular, polygonal, trapezoidal, pear (horseshoe), oblate, oval, etc. These cans are called irregular cans.

During the expanding process, the shaped cans body was slightly stretched, and the stress on the metal reached the elastic limit of the material. Before the occurrence of resistance welding, the expanding process of the shaped cans cannot withstand such a large expanding force, so the formed shape is not flat. The body of the embossed can has a large tensile force, and the stress on the metal exceeds the elastic limit of the material, and a large tensile deformation occurs. The volume of the tank body after embossing can be increased by about 20% compared with the original can body. Since the embossing can and the new-shaped shaped can both need to bear a large expanding force, only the welding seam (such as resistance welding, laser welding, etc.) can meet this expanding requirement. Because the middle section of the embossed cans has a large tensile deformation, the outer surface of the printed iron and the coating of the inner side have higher requirements to prevent damage to the printing and coating caused by this deformation. In addition to the expanding method after welding, there are also bending methods before welding. This method is often used in the can body soldering process. The can body is directly pressed into a special shape and then the can body is welded.

The price of the embossing and expanding equipment of the can body is about: USD20000-80000

Fourth, repair coating equipment

Repair coating equipment is a device that coats the weld with a protective layer that does not damage the contents and is resistant to corrosion. After welding, there is no tin layer at the weld.The inner and outer welds are in direct contact with the contents or the atmosphere and are susceptible to rust.Especially canned foods that have been processed at high temperatures and have long-term storage with high levels of acid and sulfur. There are more stringent requirements, so the inner and outer welds must be repainted. The recoater device consists of a cam body conveying system and a recoater system. The can body conveying system generally has two magnetic conveyor belts, which can continuously, smoothly and accurately feed the can body into and out of the coating area after welding.

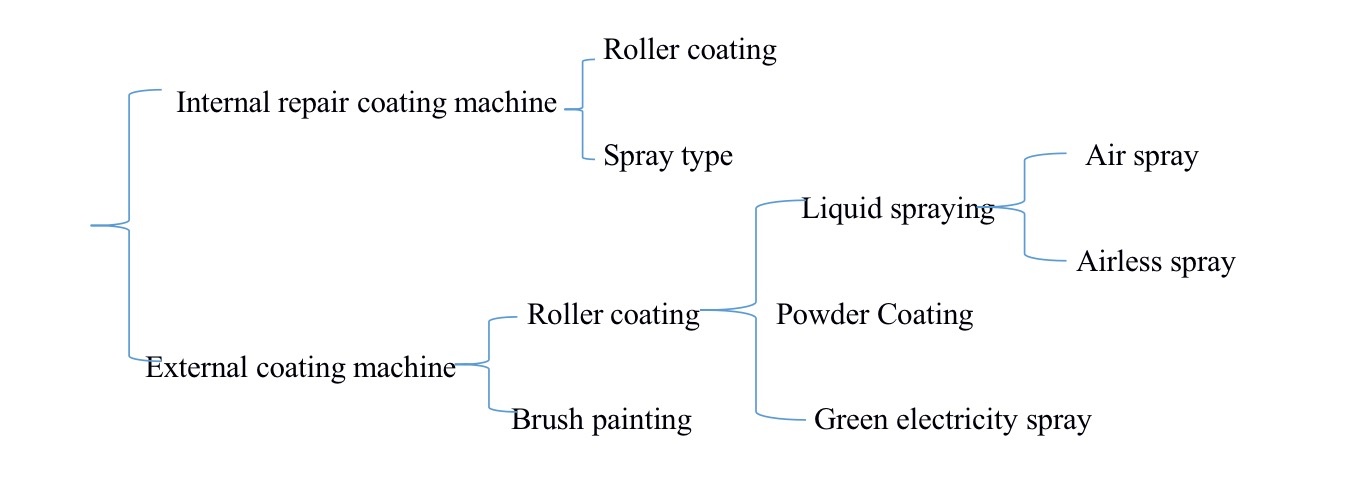

The coating equipment is roughly classified as follows:

The price of recoating equipment is about: USD5000-20000

Five, drying equipment

The coating applied on the can body must be cured by heating to make the solvent volatilize, so that the monomers can be polymerized and the anti-corrosive performance can be obtained.

Especially for foods sterilized by high temperature, the curing requirements are higher. When curing, the temperature of the surface of the can body must not be higher than the melting point of tin, and the coating must not have blistering or scorching. The curing time must be sufficient. The drying equipment consists of a can conveying system and a heating system. The conveying system generally uses chains, steel belts or belts, etc., with the aid of magnetic adsorption, the cans body is sent into and out of the heating zone. The conveying system is divided into linear conveying and circular conveying, which saves space.

The price of drying equipment is about: USD5000-15000

Six, can rolling, parting equipment

The function of the cans body rolling ribs and parting equipment is to roll the reinforcing ribs on the welded can body or cut the can body into two or three sections. A single rolling rib slitting machine cannot complete these two processes at the same time. If necessary, replace the rolling rib die or parting die and configure it as a rolling rib parter or parter. Some combination machines have multiple stations, which can be equipped with different molds at the same time to complete the rolling ribs, parting, flanging, sealing and other processes, the principle is the same.

The price of can body rolling and parting equipment is about: USD8000-30000

Seven, can necking, flanging equipment

(1)The necking machine reduces the diameter of the end of the can body, which can reduce the material consumption of the can lid, and is conducive to stacking storage and transportation of cans.

Beautiful shape. Necking is divided into ordinary single necking, large single necking, two necking, three necking, four necking and so on.

The necking method is divided into a rolling method and a shrinking method. The rolling method is a pure rolling with internal and external mold rotation, while radial feeding. Rolling method can be completed when necking and flanging thin iron necking at the same time, easy to wrinkle. The shrinking method is directly extruded by opening and closing the inner and outer molds with a cone, and is formed in one operation. Adopting multiple necking requirements: necking is even and smooth, no wrinkles, no oxide film and coating film are peeled off at the weld seam of the can body, there is no mechanical wiper or multiple stations for single shrinkage on the inner and outer surfaces of the can body, and a second shrinkable can , Three shrinkable cans, four shrinkable cans.

(2) Flanging machine: Flanging machine is a device that prepares the process of trauma and necking by clearing the two ends of the can body to the edge of the desired shape and size through the extrusion of the flanging die. Flanging methods are divided into crush type, rolling type, spinning type and plate edge type. The crush flanging uses a flanging die to extend from both ends, and hits the edges of the two ends of the can along the axial direction of the can body to form the flanges at both ends of the can body. Rolling flanging and rolling necking are completed in one step at the same time. The principle is the same as that of rolling necking. Spin-type flanging is divided into two types: one is the active rotation of the flanging roller, which has many forms; the other is the driven rotation of the flanging roller, and the two motion principles are the same. The flanging die is composed of a plurality of flanging rollers. The flanging die is extended from the two ends of the can body, and is fed along the axial direction of the can body while rotating. The two ends of the can body are squeezed to gradually complete the flanging. Flanging beads are arranged along the circumference according to a certain rule. The larger the diameter of the can body, the more the flanging roller are, and the deformation is uniform and slow. Therefore, the flanging quality is good, which is especially suitable for high-speed and thin-tin can body flanging. The flanging-type flanging is used for flanging of special-shaped cans. The outer mold holds the can body, and the inner mold moves from the inside to the outside to complete the flanging.

Flanging requirements: The flanging must meet the size, uniform and neat, and there must be no uneven width, excessive or insufficient flanging, cracks (especially at the weld), inward folds and off angles of the flanging, and peeling of the coating film.

The price of can necking and flanging equipment is about: USD8000-30000

The above prices are for your reference. The specific prices need to be determined according to the actual supporting conditions.