10-25L Neck-in Drum Production Line

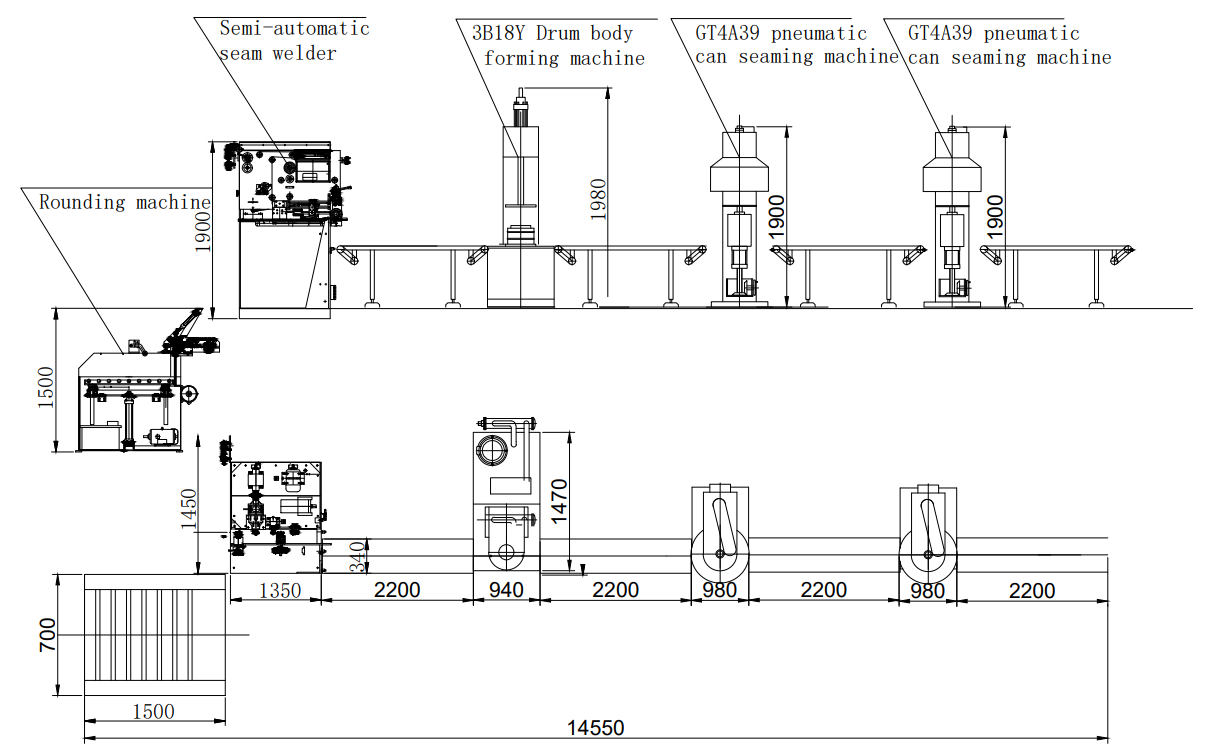

The production line is suitable for the semi-automatic production of 10 liters to 25 liters’neck-in drum . total power: approx.35KW,total floor space: 65㎡ .total length:approx.15 meters. total manpower: 7-8 people. Production capacity: 12-17cpm. Drum height range: 170-460mm. Drum diameter range:220-280mm

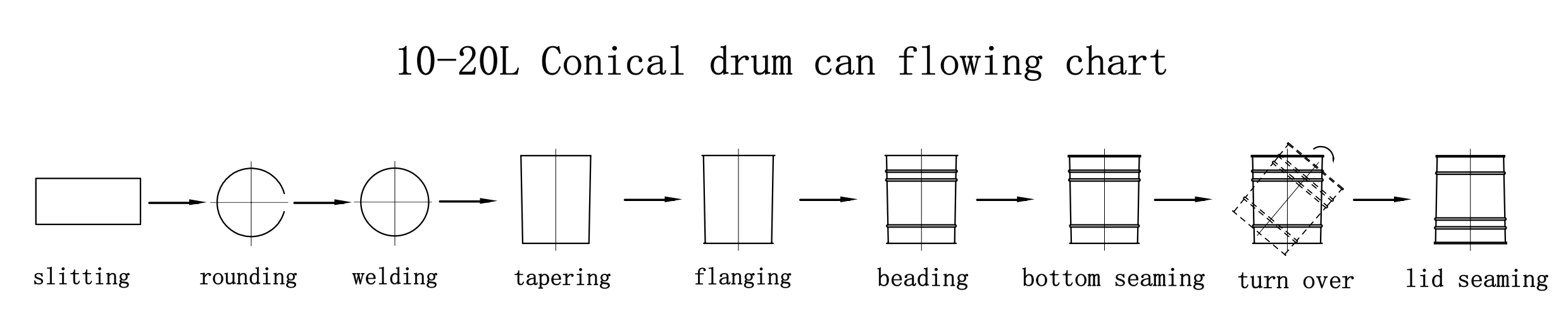

Working Process:Semi-automatic Slitting→Semi-automatic Rounding Machine→Semi-automatic Front-Feeding Seam Welding→Semi-automatic Tapering&Flanging&Beading→Semi-automatic Bottom Sealing→Semi-automatic top sealing.

What is a neck-in drum?

It is made of three pieces of metal (mostly tinplate) : the body, the bottom and the lid of the cans. The cans is conical or cylindrical shape. The body of the cans has two ribs. The scope of closed barrel: capacity 10-25l, diameter 220-280mm, height 170-460mm.

Equipment composition of semi-automatic neck-in drum production line

GT1B5B Can Slitting Machine

| Maximum thickness of cutting iron sheet | 0.18-0.5mm |

| Maximum width of cutting iron sheet | 1000-1250mm |

| Minimum width of cutting sheet | 40mm |

| Motor Power | 1.65KW |

| Dimensions(L*W*H) | (1470)1720×1000×1100mm |

| Device Weight | 1200-1500KG |

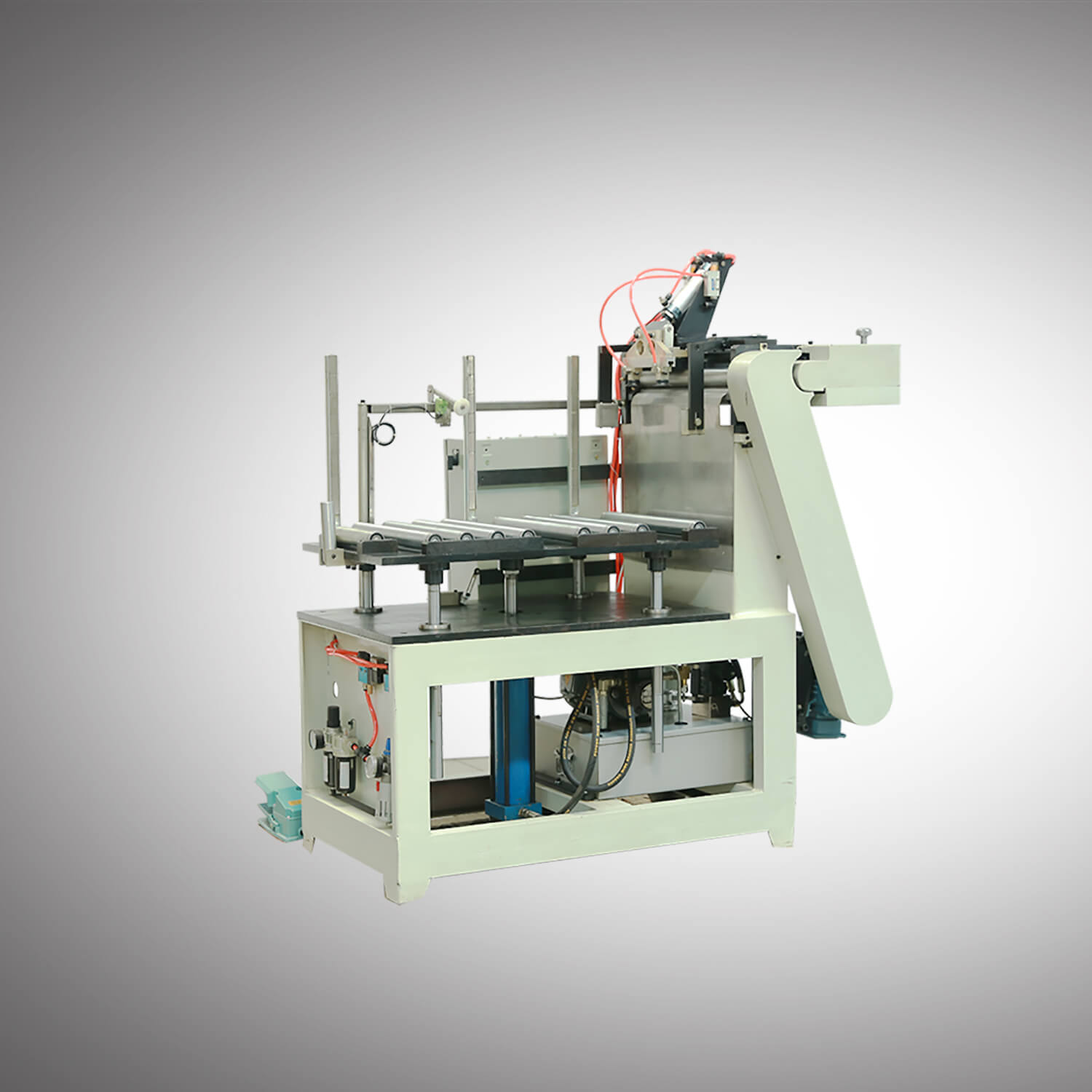

Automatic Rolling Machine

| Power supply | AC380V/50HZ |

| total power | 0.75KVA |

| thickness | 0.2-0.4mm |

| pneumatic system pressure | 40L/min Mpa |

| can height range | 120-400mm |

| diameter range | Φ105-286mm |

| rounding speed | 40m/min |

| Dimensions(L*W*H) | 1500*700*1500mm |

Rear-feeding seam welder machine

| WeldingSpeed: | 6~12m/min(weldingpowerfrequency:50~240Hz) |

| Capacity: | 10~50cans/min |

| Diameter: | Φ52~180mm、Φ65~290mm |

| Height: | 70~270mm、70~420mm |

| Material: | 50#~100#Tinplateplate、steelbaseplate |

| Thickness: | 0.18~0.38mm |

| Overlap: | 0.4~1.2mm |

| Controlway: | PLC |

| Coolingwater: | ≤20℃ |

| Waterflow: | 20L/min |

| Waterpressure: | 5kg/cm² |

| Installationcapacity: | 16KVA |

| Dimensions(L*W*H) | 1350×1450×1900mm |

| Device Weight | 1200kg |

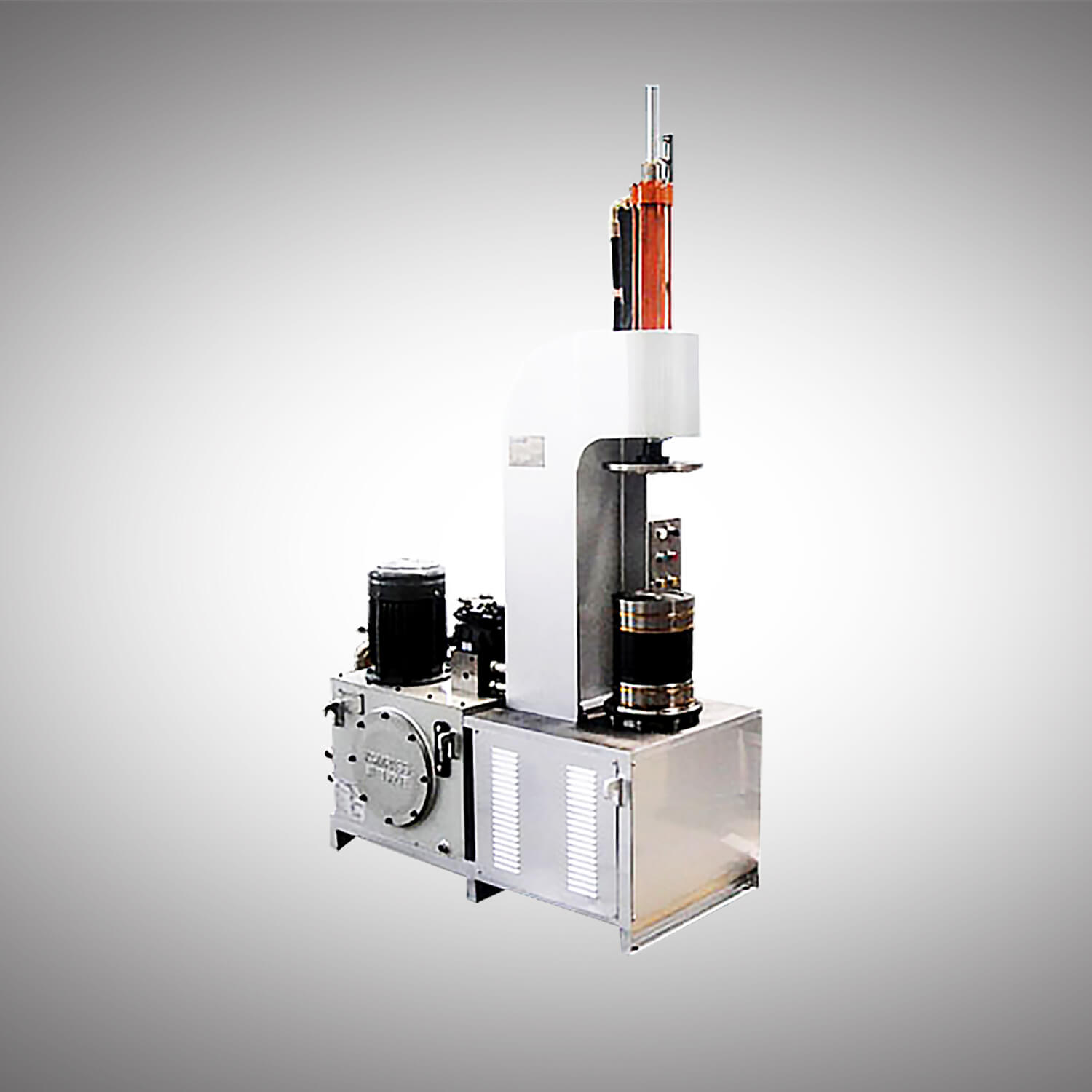

3B18Y Drum body forming machine(10-25L)

| thickness | ≤0.4mm |

| diameter range | 220-280mm |

| can height range | ≤400mm |

| production capacity | 12-17cpm |

| Motor Power | 7.5KW |

| Device Weight | 1080KG |

| Dimensions(L*W*H) | 1500×900×2300mm |

GT4A39 Pneumatic round can seamer

| thickness | ≤0.4mm |

| diameter range | 220-300mm |

| can height range | ≤400mm |

| production capacity | 15-20cpm |

| Motor Power | 2.2KW |

| Device Weight | 980KG |

| Dimensions(L*W*H) | 980*580*1900mm |

The layout of the production line

Tin can making artcraft

The following products are produced by this equipment

Preparation for Production

I Factory workshop preparation:

Reserve the main cable model: YJV3*25+2*16

Area: At least 25 meters long by 10 meters wide, totaling 250 square meters

Flow rate: 134 liters per minute.

Pressure requirement: 0.4-0.8 Mpa

Number of workers:7-8people

II Preparation of production materials

1、 Top lid, bottom lid, earpiece

① You can directly purchase top lids, bottom lids, and earpieces. In China, there are many specialized lid manufacturing factories that offer various specifications to choose from. If you have specific size requirements, you can request the lid factory to create custom molds for production. Once the production quantity reaches a certain threshold, the cost of mold fabrication is often waived or included for free.

2、 Can body material of printed tinplate

① You can directly purchase can body materials. In China, there are many professional printing tinplate factories that can customize can body materials according to your requirements.

3 Copper wire, adhesive, powder, plastic handles, plastic press-on caps, iron press-on caps.

These materials can be directly purchased worldwide.

Application industry

This production line is applicable to the production of metal round cans for food, medicine, chemical industry, paint, cooking oil and other industries. It can also be used in the production of food cans, paint cans, edible oil cans, paint cans, milk powder cans, aerosol cans, etc.

Applicable countries and regions

Applicable to countries or regions where labor is difficult, unstable, or highly paid. For example: malaysia, indonesia, philippines, vietnam, thailand, india, dubai and so on.

Applicable to countries or regions with high output and high product quality. For example: saudi arabia, dubai, russia, canada, south korea, turkey and so on.

Why to chooes ISHIN products?

- Established 20 years ago, ISHIN technology is a well-known brand in the Chinese industry.

- More than 80% of customers in China have used ISHIN products.

- ISHIN technology has a strong technical team and professional after-sales service to provide customers with turnkey project and one-stop service.

- Once choosing ISHIN technology products, ISHIN technology will provide you with the most professional technical advice and guidance from material selection, printing and typesetting, installation, commissioning to smooth production