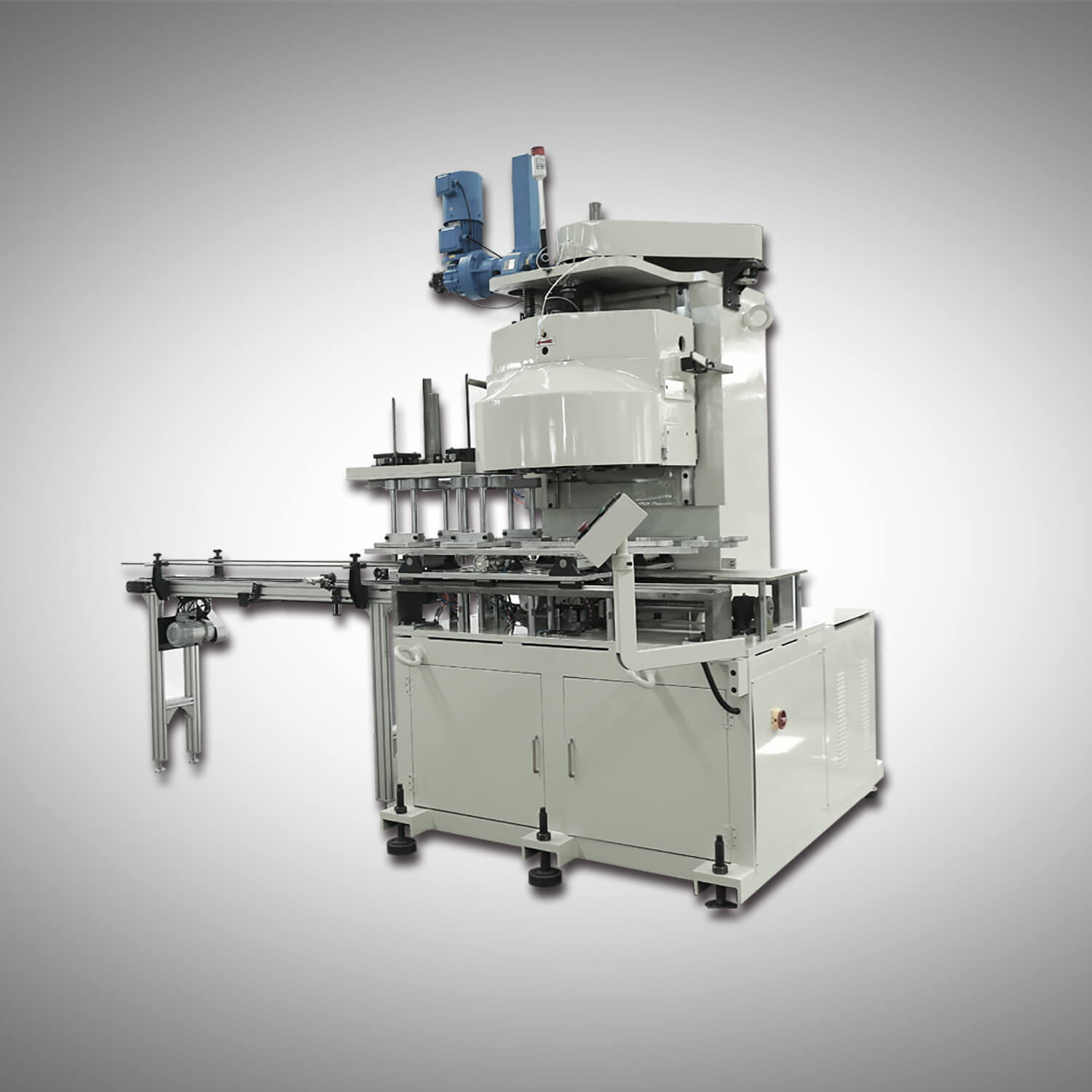

Automatic Can Sealing Machine

The fully automatic can sealing machine series can be used in various can factories for sealing tinplate packaging cans. Such as: packaging cans for various food, cooking oil, paint, motor oil, etc. It is mainly suitable for the sealing of 3L-4L Retangular cans, 16L-20L conical pail and neck-in drum 18L-20L square cans and 1-5L round cans.

What is a three-piece can?

The application history of three-piece cans has been nearly 200 years. Although it has been improved many times, its basic composition is still made of three metal sheets (mostly tinplate) of can body, bottom and lid, with the name “three-piece can” . The shape, size and manufacturing method of the bottom and lid of the ordinary three-piece can are exactly the same, and they are collectively called the lid. There are two main sealing forms for the can body: soldering and welding. The former was used earlier, but due to the lead in the solder, it has been eliminated; the latter can avoid lead pollution, low energy consumption, and low material consumption , but the production equipment is complicated.

Three-piece cans have good characteristic, can produce cans of various shapes, high material utilization, easy to change size, mature production technology, and many types of packaging products.

Working process of fully automatic can sealing machine production line

Before entering the main engine,the can stop cylinder will let the can body go one by one separately.On left of machine head,there is an automatic can lid splitting device. Operater only need to put stacks of lids, which have been curled,into the hopper.While working,the lid splitting blade will make the lids separate one by one driven by cylinder.A positioning cylinder of the can body is installed on the conveying rack under the lid splitting base to block the can body.It will make the can body directly stop under the lid and wait for the lid to fall.At this time, the can holding mold will come to hold the can body and lid together, and then positioning cylinder releases them one by one,and carry the can body and lid to another working station. Another set of can holding mould will send the can body and lid to the first seamer to seal. The position of the positioning cylinder can be adjusted a little according to the size of the can body.The can holding molds and the pushing molds are mounted on two symmetrical long sliding plate, which are connected with the ball screw rods and the ball screw rods connected with the servo motor moves the can body holding molds back and forth.When working, the can holding mould shall hold the body and lid at the same time and send them to the underside of the machine head for sealing.Meanwhile, the can pushing mold mounted on the same sliding plate with the can holding mold pushes the can body with sealed lids onto the conveyor belt of the middle conveying rack.After the can body’s running for a certain distance, it is turned over by the reversing device.When the can body runs to the front of the second seamer, the former same operations will be repeated. The can body and lid are held together by the holding mold, and sent to the second machine head to finish sealing.The same action as the first seamer.At this point, the top and bottom seals of an empty can are completed.

Fully automatic can sealing machine series

GT4B30 Automatic can sealing machine

| production capacity | 25-30cpm |

| diagonal range | Φ200-300mm |

| can height range | 170-460mm |

| thickness | ≤0.4mm |

| total power | 4.55KW |

| pneumatic system pressure: | 0.3-0.5Mpa |

| the front section conveyor’s size | 2780*310*750mm |

| seaming machine size | 1350*1290*1980mm |

| electric carbinet size | 600*350*1400mm |

| main machine weight | 3T |

10-20L 8-Rollers Automatic square can seamer

| production capacity | 20-22cpm |

| diagonal range | 300-320mm |

| can height range | 170-450mm |

| thickness | ≤0.4mm |

| total power | 3.75KW+lid feeding 0.2KW |

| pneumatic system pressure: | 0.3-0.5Mpa |

| the front section conveyor’s size | 2780*310*750mm |

| seaming machine size | 1350*1290*1980mm |

| electric carbinet size | 600*350*1400mm |

| main machine weight | 3T |

1-5L Automatic can sealing machine

| production capacity | 35cpm |

| diagonal range | 50-190mm |

| can height range | 80-350mm |

| thickness | ≤0.35mm |

| total power | 5.13KW |

| pneumatic system pressure: | 0.5Mpa |

| the front section conveyor’s size | 2740*260*880mm |

| seaming machine size | 1320*1120*2120mm |

| main machine weight | 2.5 |

RA52-180 Automatic small round can sealing machine

| Production capacity (cans/min) | 40-60 |

| Diameter (mm) | 50-180 |

| Can Height (mm) | 60- (270) 300 |

| Thickness of tinplate (mm) | 0.16-0.4 |

| Power (kw) | 3.5 |

| Max. spin rate of seamer head (rmp/min) | 500 |

| Voltage (v) | 380 |

| Size (mm) | 5000×885×1800 |

| Weight (kg) | 1750 |

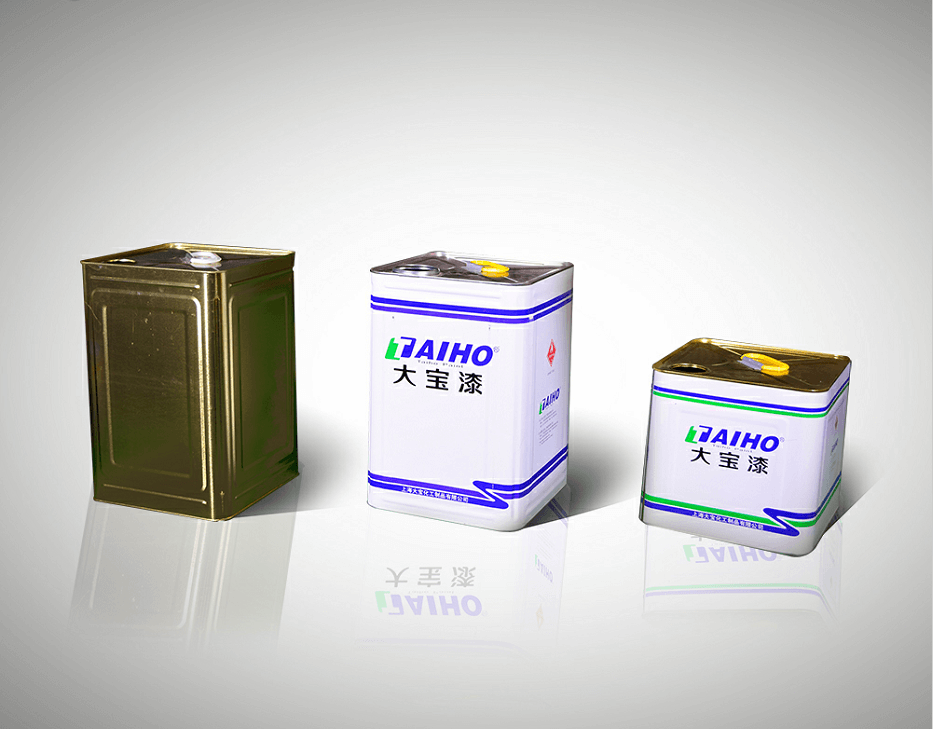

The following products are produced by this equipment

Advantages and disadvantages of the fully automatic can sealing machine production line

Advantages: the can sealing machine adopts automatic computer programming control system, fully realizing the full automatic sealing machine work.Only 1-2 workers are needed to complete the operation of the entire machine.The can sealing machine has fast production speed, high production efficiency, automatic fault detection system and low rejection rate.

Disadvantages: compared to semi-automatic sealing machine, the initial investment capital is larger. For the start-up enterprises, it is recommended to use semi-automatic sealing machine with less capital in.

ISHIN products and peer products comparison

ISHIN machines: The can making machine are processed with high hardness and imported wear-resistant materials. The imported guide rail and profile are combined with precise coordination of servo motor to ensure a fast conveying system. Four rounds, six rounds,Eight-wheel can sealing machine head, The sealing quality is stable and fast .At the same time, the sealing machine head adopts special design, which has the characteristics of low noise and high efficiency.

Counterparts machines: most of the can making machine is made of domestic materials, common profile and domestic guide rail, combined with stepping motor,Which will be in some lack of stability and accuracy.Can sealing machine head only has four rollers, quality and speed will have a certain impact .At the same time the machine head adopts the old design, the production noise is bigger.

Application industry

This production line is applicable to the production of metal round cans for food, medicine, chemical industry, paint, cooking oil and other industries. It can also be used in the production of food cans, paint cans, edible oil cans, paint cans, milk powder cans, aerosol cans, etc.

Applicable countries and regions

Applicable to countries or regions where labor is difficult, unstable, or highly paid. For example: malaysia, indonesia, philippines, vietnam, thailand, india, dubai and so on.

Applicable to countries or regions with high output and high product quality. For example: saudi arabia, dubai, russia, canada, south korea, turkey and so on.

Why to chooes ISHIN products?

- Established 20 years ago, ISHIN technology is a well-known brand in the Chinese industry.

- More than 80% of customers in China have used ISHIN products.

- ISHIN technology has a strong technical team and professional after-sales service to provide customers with turnkey project and one-stop service.

- Once choosing ISHIN technology products, ISHIN technology will provide you with the most professional technical advice and guidance from material selection, printing and typesetting, installation, commissioning to smooth production