For a long time, the packaging image of domestic canned lunch meat products has been solidified as the mainstream of tinplate rectangular three-piece cans with longitudinal welds (hereinafter referred to as “three-piece rectangular iron cans”) and matching tinplate rectangular easy-open lids, supplemented by Imported aluminum rectangular deep-drawn two-piece cans (hereinafter referred to as “two-piece rectangular aluminum cans”) and matching aluminum rectangular easy-open lids. Both types of packaging seem to have fallen into an innovation dilemma in terms of eliminating application pain points and improving retail shelf effects, not to mention the increase in the added value of consumer products.

Application pain points of three-piece rectangular iron can and two-piece rectangular aluminum can

Three-piece rectangular iron can application pain points Three-piece rectangular iron cans and matching rectangular iron lids have brought two stubborn problems: on the one hand, the welding seam area of the can body and the easy-opening lid engraving area are prone to vulcanization and contaminate food; on the other hand , the iron cover makes it difficult for ordinary consumers to open, resulting in a decrease in user friendliness.

Application pain points of two-piece rectangular aluminum cans Although importing two-piece rectangular aluminum cans and matching rectangular aluminum lids can solve the above problems, there are still some application pain points, which are highlighted in the following four aspects.

First, because the empty cans cannot be nested, and long-distance transportation will cause the cost to rise sharply, resulting in limited sales scope.

Second, it is not easy to demould, and it is easy to damage the original shape of the luncheon meat.

Third, because the aspect ratio is greater than 1, it is difficult to control the printing deformation after the container is formed if the sheet is printed before stretching, and there is no supporting printing equipment that can directly print on the can body.

Fourth, import costs are high. This has also resulted in the limited application of this type of packaging in the domestic canned luncheon meat market—most of the canned luncheon meat in two-piece rectangular aluminum cans currently sold in China are still imported products, or foreign brands produced in China .

Conical two-piece square aluminum can: integrates many advantages such as nesting and easy release

In view of this, our R&D team, after repeated research and tests, has developed an aluminum square expanded neck belt taper stretched two-piece can F862 (utility model patent: ZL202020883373.9; appearance patent: ZL202030645142.X, hereinafter referred to as “conical” Two square aluminum cans”), and the exclusive matching F88mm square aluminum high-temperature cooking and easy-opening lid (utility model patent: ZL202020886205.5; appearance patent: ZL202030646351.6, hereinafter referred to as “square cooking-resistant aluminum lid”), except for the It completely solves the application pain points of the aforementioned two types of packaging, and can also give consumers a visual impact from the appearance of the packaging, and at the same time, it also brings unexpected dish presentation effects on the consumer side.

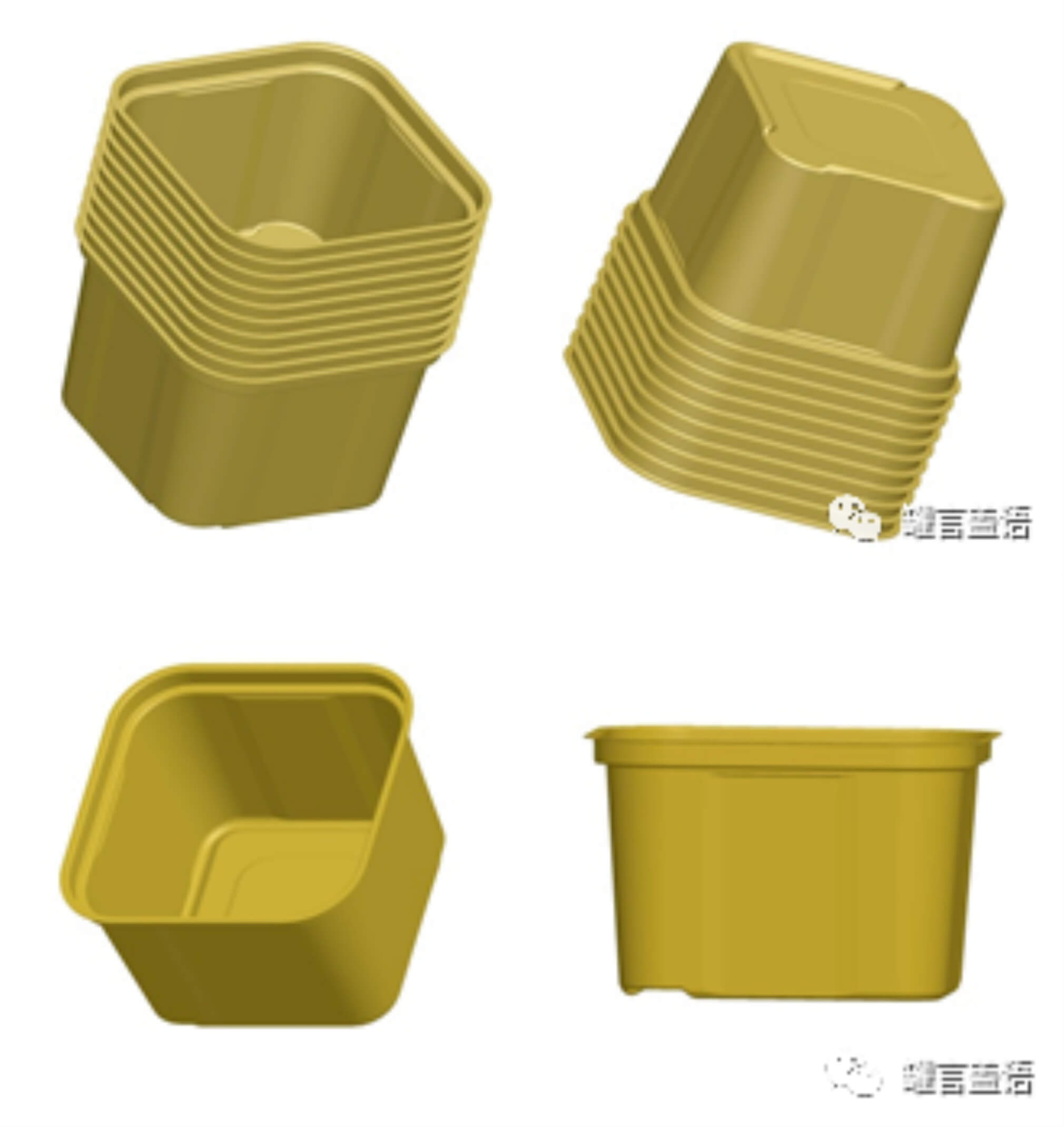

Figure 1 Aluminum conical expanded neck square two-piece can and matching square aluminum high temperature cooking easy-open lid

The advantages of the positive piece-shaped retort-resistant aluminum cover Compared with the traditional rectangular iron cover, the aluminum cover is easier to open; at the same time, it also eliminates the problem of oxidation and rust of the engraved line and the edge of the roll seal caused by long-term shelf storage. In addition, since the inner and outer rivet areas and the engraved area of the aluminum cover do not need to be repainted, the production cost is lower than that of the iron cover, and the process is more environmentally friendly.

Advantages of the conical two-piece square aluminum can First, because the can body is stamped and formed in one piece, the problem of food contamination caused by the vulcanization of the welded seam of the three-piece iron can is completely solved.

Second, the tapered body and neck flare design brings many of the following benefits. First, demoulding lunch meat is no longer a problem. The second is that the taper can body can be nested, which greatly reduces the cost of empty can transportation, so that there is basically no geographical difference between food manufacturers and can manufacturers. The third is to use telescopic automatic canning technology (the gap between the can walls is sufficient to avoid scratches on the coating) in the process of canning collection and packaging and canned food filling, which can reduce waste and defective products during packaging and transportation. Rate.

Third, since the height-diameter ratio is less than 1, the square can can be directly printed on the sheet material before being punched into shape; coupled with the eye-catching design that is different from traditional products, the shelf impact of canned products is significantly enhanced, which helps in brand promotion. It should be noted that the capacity of the square cans that our company has brought to the market is the same as the traditional rectangular three-piece cans.

Fourth, the shape of the luncheon meat poured from the square jar breaks the tradition and is more beautiful. At the same time, it brings better dishes presentation and platter effect to the terminal consumption places such as central kitchens, restaurants, hotels, etc., which is expected to improve the traditional canned luncheon meat. The added value of food.