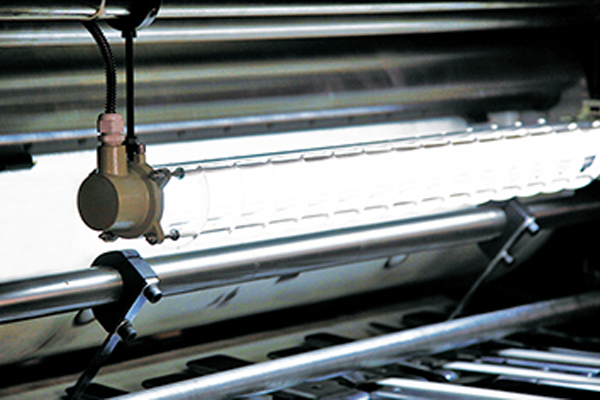

HYP45B-VI Metal Sheet Six-Color Offset Printing Machine

Technical performance: The main transmission gear is located in the protective cover of the machine. The lubrication is sufficient and the service life is long; the three printing cylinders are arranged vertically, which is easy to operate; the printing cylinders are all supported by imported precision bearings to ensure the rotation accuracy of the cylinders: the pressure adjustment structure of the plate roller Advanced, easy to operate: Shaftless transmission technology is adopted, each color group is independent of each other, and the plate and wiper cylinder can be installed at the same time; synchronous transmission technology is adopted between color groups, and the virtual main axis is used as a reference to achieve high-precision synchronization.

Technical Advantages

The main transmission gear is located in the shield of the machine. The lubrication is sufficient and the service life is long;

The three printing cylinders are arranged vertically, which is easy to operate;

The printing cylinder is supported by imported precision bearings to ensure the rotation accuracy of the cylinder:

The pressure adjustment structure of the form roller is advanced and easy to operate:

Using shaftless transmission technology, each color group is independent of each other, and can be loaded with plates and wiped rollers at the same time;

The synchronous transmission technology is adopted between the color groups, and the virtual main axis is used as a reference to achieve high-precision synchronization

Printing dots are firm and clear;

The roller adopts hard lining method,

Adopt cam high point closed teeth, reliable positioning, accurate overprint:

The plate cylinder adopts alcohol dampening, and the printing ink is bright;

The plate roller and cylinder clutch are driven by air cylinder, with simple structure and reliable operation:

The water fountain roller and the ink fountain roller are driven by a separate frequency conversion motor, which can be adjusted steplessly to achieve synchronous tracking with the speed of the main machine:

Scientific and reasonable arrangement of ink rollers ensures the quality of ink supply in the system;

The drive of the ink supply system and dampening system can be disengaged from the main machine as needed to avoid dry wear of the rubber roller:

Man-machine interface, intuitive screen, easy to master, easy to operate:

The synchronization between the feeder and the main machine can be adjusted electrically without stopping the machine, effectively shortening the auxiliary time

Fixed-point, quantitative, and timing lubrication system is adopted, and the lubrication is sufficient without oil leakage.

Technical Parameters:

| Maximum sheet metal size | 1145X965mm |

| Minimum sheet metal size | 712X508mm |

| Sheet metal thickness range | 0.16-0.50mm |

| Maximum printing area | 1135X945mm |

| plate size | 1160X1040X0.3mm |

| Blanket size | 1175X1135X1.9mm |

| The size of the white side of the mouth | 5mm |

| machine speed | 6000 sheets/hour |

| printing speed | Determined according to printing parameters |

| Maximum Stacking Weight | 2 tons |

| Machine size (length X width X height) | 21530X3700X2460mm (with sample table) 18580X3700X2460mm without viewing table) |

Why to chooes ISHIN products?

- Established 20 years ago, ISHIN technology is a well-known brand in the Chinese industry.

- More than 80% of customers in China have used ISHIN products.

- ISHIN technology has a strong technical team and professional after-sales service to provide customers with turnkey project and one-stop service.

- Once choosing ISHIN technology products, ISHIN technology will provide you with the most professional technical advice and guidance from material selection, printing and typesetting, installation, commissioning to smooth production